-40%

Portable Sand Blasting Machine Jewelry Small Sandblasting Machine Tools 220V O

$ 76.03

- Description

- Size Guide

Description

Portable Sand Blasting Machine Jewelry Small Sandblasting Machine Tools 220VSpecification:

Voltage: 220V, 50Hz

Weight: 9.5kg,

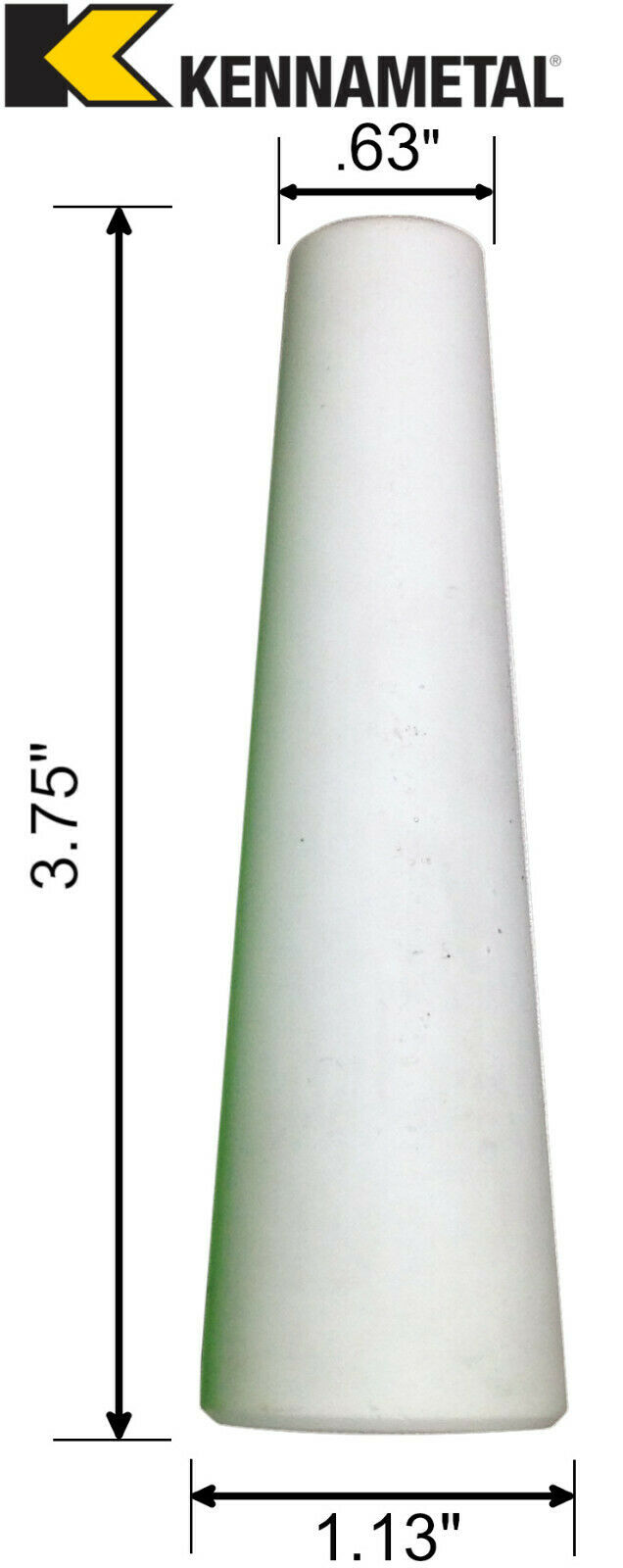

Size: 410*280*360mm

The machine is required to use with an air compressor. The pressure to 0.5MPa or more.

The use of sandblasting machine:

1. Surface cleaning

Oxide after heat treatment, residual salt, residual oil, etc.; black (a) the oxidation of skin color casting, sand, etc.; no residual oxide processing precision casting, sand, etc.; Machined Products residues, micro-burr, etc.; oxide welding parts, welding slag, etc.; cold, hot-rolled steel plate (steel) of the oxide coating, corrosion layers; a variety of mold cavity mold release agents, sediments, etc.; the surface of the sintered ceramic components residue; plastic molding parts of the flash; the surface of radioactive elements; bridges, hydropower gate, ship, building; airport runway rubber adhesion layer; train cars; various pipes and tank containers; the old parts of the oil, attachments, etc.; container residual paint, rust layer and attachments, etc.; porcelain sintering on the wrong layer; decoration scratched the surface ... ....

2. Surface pre-treatment before coating

Paint, paint the former; spray before; metal before spraying; zinc, chromium, nickel ago; oxidation front; testing before the ... ...

3. Change the mechanical properties of the workpiece surface roughness increase or decrease; change the surface tension stress is compressive stress; enhance the surface lubrication; reduce the noise coupled parts of the movement; improve surface friction coefficient ...

4. Workpiece surface finishing process

Polished metal surface decoration; get matte or diffuse surface; polishing the surface of wood products ...

5. Parchment and other clean-up and preservation of works of art

6. Cleaning brush, such as contactors and wiring technique the surface, to improve the electrical properties

Sandblasting machine advantages:

1. Sandblasting machine metal parts of the base from damage, dimensional accuracy will not change;

2. Part surface is not contaminated, abrasive material will not be with the parts for the chemical reaction;

3. Sandblasting machine can easily handle groove, concave and other difficult to access the site, a variety of abrasive particle size can choose to use;

4. A significant reduction in processing costs, mainly reflected in the improvement of the efficiency of blasting machines, to meet the requirements of a wide range of surface finishing;

5. Low energy consumption, cost of province;

6. Sandblasting machine does not pollute the environment, eliminating the need for environmental control costs;